Application > Can production

Every company in the packaging branch needs reliable monitoring of material on conveyors. The demands for sensors to guarantee an efficient and uninterrupted production are high: material or gaps shall be identified, the size of the cans must to be checked, jams on the conveyor announced.

This was also the case in a company in the beverage industry: The occupancy of the can line was to be monitored and signals for can jam and movement were to be supplied. The requirement was solved with the DLU 001.28 GZ S4 inductive can line sensor with two integrated response zones. These two response zones of different sizes with adjustable switch-on and switch-off delays allow the conveyor line to be monitored for different operating sequences.

In addition to the mentioned inductive sensor strip with two response zones, Proxitron also offers products with one response zone with integrated on and off delay. This allows can lines to be controlled for occupancy even in the case of production-related gaps in the conveyor line or in the case of larger cans. A signal is activated when the sensor area is fully loaded. If this is missing for a defined period of time, the can line has an unwanted gap and the conveying speed must be increased.

At a glance

- Monitoring of roller path and conveyor track

- Recognisation of jams, allocation and supply

- Speed monitoring

- Connection by plug or cable variations

- Can counting

- Detect or hide gaps

Specially for can lines

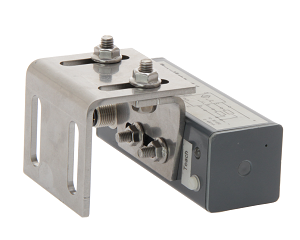

As an accessory choose the mounting (angled) bracket HM 7. The bracket allows, in combination with the mounting bracket HM 8 or HM 9 (different sizes), an easy installation of inductive sensors of the series IKU 0 in can lines. An adaption to existing Sencon-mounting brackets is possible.