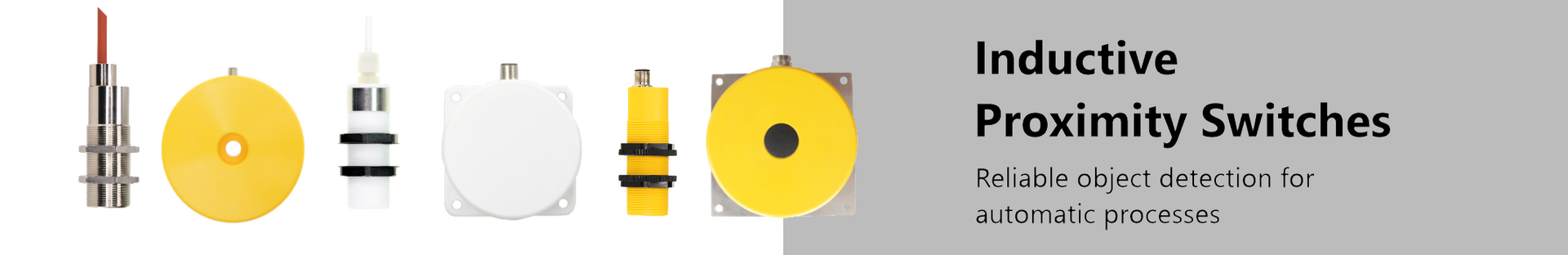

Our Sensors > Inductive Sensors

Proxitron inductive sensors are robust and sensitive at the same time. They are ideal for the non-contact detection of metal objects. Use our sensor selector to chose your inductive sensor.

A metal object which is located within the sensor range of the proximity switch, changes the electromagnetic field and creates a switching signal. Positions of metal objects or parts of machines can be detected safely and maintenance free. The key benefit of the proximity switch is that it is not sensitive to water and pollution.

Our sensors with extremely high sensing distance enable metal detection even where conventional standard sensors are overwhelmed. Furthermore, Proxi-Teach® technology offers safe operation under all conditions. PROXITRON inductive proximity sensors are therefore found in a wide range of applications in the steelmaking and metalworking industries and are preferred by many plant and machine builders "when the heat is on".

Depending on the sensor type, our selection of can sensors is predestined for the production and filling of cans, for counting metal cans on conveyor belts or for increasing the efficiency of a plant in the production of cans. Reliable control of the feeding of small parts, such as screws or nails, this is possible with our ring sensors. For application in chemically aggressive environment our sensors in PTFE housing are suitable.

Additionally to the great selection of industrial standard solutions we offer adapted variants or single individual solutions for complex applications. Our experience makes it possible to understand your request, identify possible problems and to solve them.

How does an Inductive Proximity Switch work?

The sensor generates a high-frequency electromagnetic field. When a metal object enters this field, the electrical conductivity changes, which is detected by the sensor’s internal circuit. This allows the switch to operate precisely and reliably, even in harsh industrial environments.

Where are Inductive Proximity Switches used?

Proxitron Inductive Proximity Switches are used wherever reliability and precision are essential – in rolling mills, foundries, automation systems, production lines, and conveyor equipment. Typical applications include position and end-stop detection, speed monitoring, and presence control of metallic components.

What are the advantages of Proxitron Inductive Proximity Switches?

High temperature resistance up to +230 °C

Rugged design for dust, dirt, and vibration

Long service life thanks to wear-free technology

Reliable switching accuracy under demanding conditions

Made in Germany – engineered and manufactured for continuous industrial use

Was sind ProxiHeat und ProxiPolar Sensoren von Proxitron?

Die ProxiHeat und ProxiPolar Serien von Proxitron sind induktive Sensoren für extreme Umgebungsbedingungen. Während ProxiHeat Sensoren für den Einsatz bei sehr hohen Temperaturen entwickelt wurden, sind ProxiPolar Sensoren speziell für den Betrieb in Kälte und Frost konzipiert. Beide Serien vereinen Präzision, Robustheit und Langlebigkeit – Made in Germany.

What are Proxitron can sensors?

Proxitron Can Sensors are special inductive sensors designed for use in can manufacturing and packaging lines. They are used for detecting, counting, and monitoring cans made of aluminium or tinplate at high production speeds – reliably and without contact.

How do Proxitron inductive sensors improve process reliability?

With their high switching accuracy, fast response times, and extreme durability, Proxitron sensors ensure reliable process monitoring. They help prevent malfunctions, reduce downtime, and significantly contribute to plant availability and product quality.

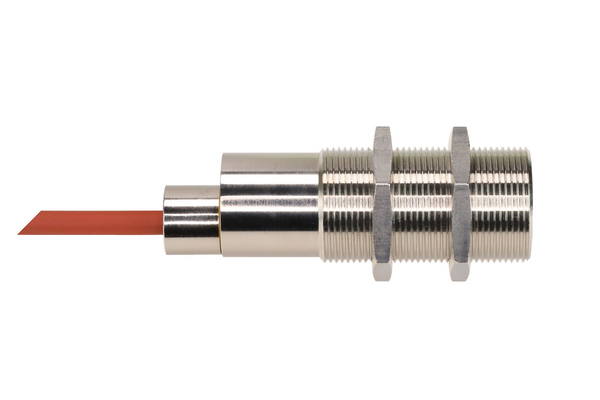

What housing designs and connection types are available?

Proxitron offers Inductive Proximity Switches in various sizes, thread types, and connection options – from compact M12 sensors to robust high-temperature housings with cable or plug connections. This ensures easy integration into existing control and automation systems.

Write to us by email at sales@proxitron.de, use our contact form or call us on 04121 2621-0.

Our team will be pleased to advise you and provide you with all the information you need!

![[Translate to English:] Proxitron Drehzahlwächter](/downloads/_processed_/b/2/csm_Proxitron_Drehzahlw%C3%A4chter_Stecker_-_Kopie_ae2afd8ff2.png)