Application > Production of 3-piece cans

Special sensors from Proxitron have already been integrated into this manufacturing process worldwide for decades.

You can take advantage of our extensive experience from numerous projects worldwide with manufacturers of can production lines and system and machine builders for this sector. Can sensors from Proxitron are in use in thousands of machines, affordable, and especially easy to adjust with their teach-in technology.

Production of 3-piece cans

The history of the tin can began more than 200 years ago. In 1804 the Frenchman Nicolas-Francois Appert, a bakery chef and confectioner from Paris, recognised the benefits of tin cans for foods in combination with sterilisation by heat. He also cooked perishable food in the can and thereby made it non-perishable.

Today, the food and beverage industry is hardly imaginable without the can. Around 15 billion cans are produced in Europe alone, which is just a fraction of worldwide production. The can is also making a major comeback in Germany 12 years after introduction of the deposit. Around 1.9 billion beverage cans are sold in Germany alone, demonstrating a growing trend.

Basically the production process is differentiated between a 2-piece can - such as a beverage can - and a 3-piece can - i.e. for canned foods. Inductive proximity switches, can sensors, and can counting sensors from Proxitron are used for both can types.

Manufacturing process for 3-piece cans

Tin plate and aluminium plate are the predominant materials used for cans. Approximately 70 per cent of the tin plate manufactured worldwide is used for the production of food and beverage cans.

A coating is applied to the plate, which is then dried in a drying oven. Shears cut the plate to the necessary size for further processing

The 3-piece food can comprises the tubular tin plate body with longitudinal seam where the can is welded or crimped. The resulting can body is also called a blank.

After they are filled, food cans are sealed air-tight by crimping. Can sealing machines are used for this purpose. In some cases, these machines have a large number of individual sealing stations.

After they have been sealed, the cans are pasteurized or sterilised in an autoclave in order to make them non-perishable.

Do you have a application?

Then send us an e-mail to sales(a)proxitron.de or fill out our contact form.

- Inductive proximity switches of the type IKK 060 recognise and monitor the flow of the cans

- Inductive sensor strips of the type IKU 015 or IKU 011 are installed along the conveying sections and assure optimal advancement from one process step to the next and the downstream logistical process steps until the palletising.

- Inductive proximity switches for high-temperature applications monitor the drying oven processes.

- Inductive can counting sensors of type DZU 001 count up to 6000 cans per minute reliably and compensate counting errors in case of vibration or reverse running.

Your benefit, your advantage

Maintenance-free

Simple adjustment with the help of a teach-in function

High availability

Extremely robust

40 years of application experience worldwide

Provision of samples for a test period

Application consulting / analysis

Practical accessories,

specially for can lines:

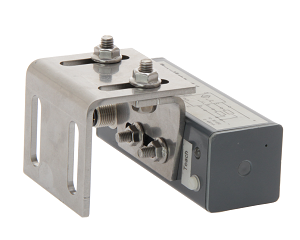

Decide for the HM7 mounting bracket as accessory.

The HM 7 allows, in combination with mounting bracket HM 8 or HM 9 (different sizes), the easy installation of inductive sensors series IKU 0 at the can line. An adaption at existing Sencon mounting brackets is possible.