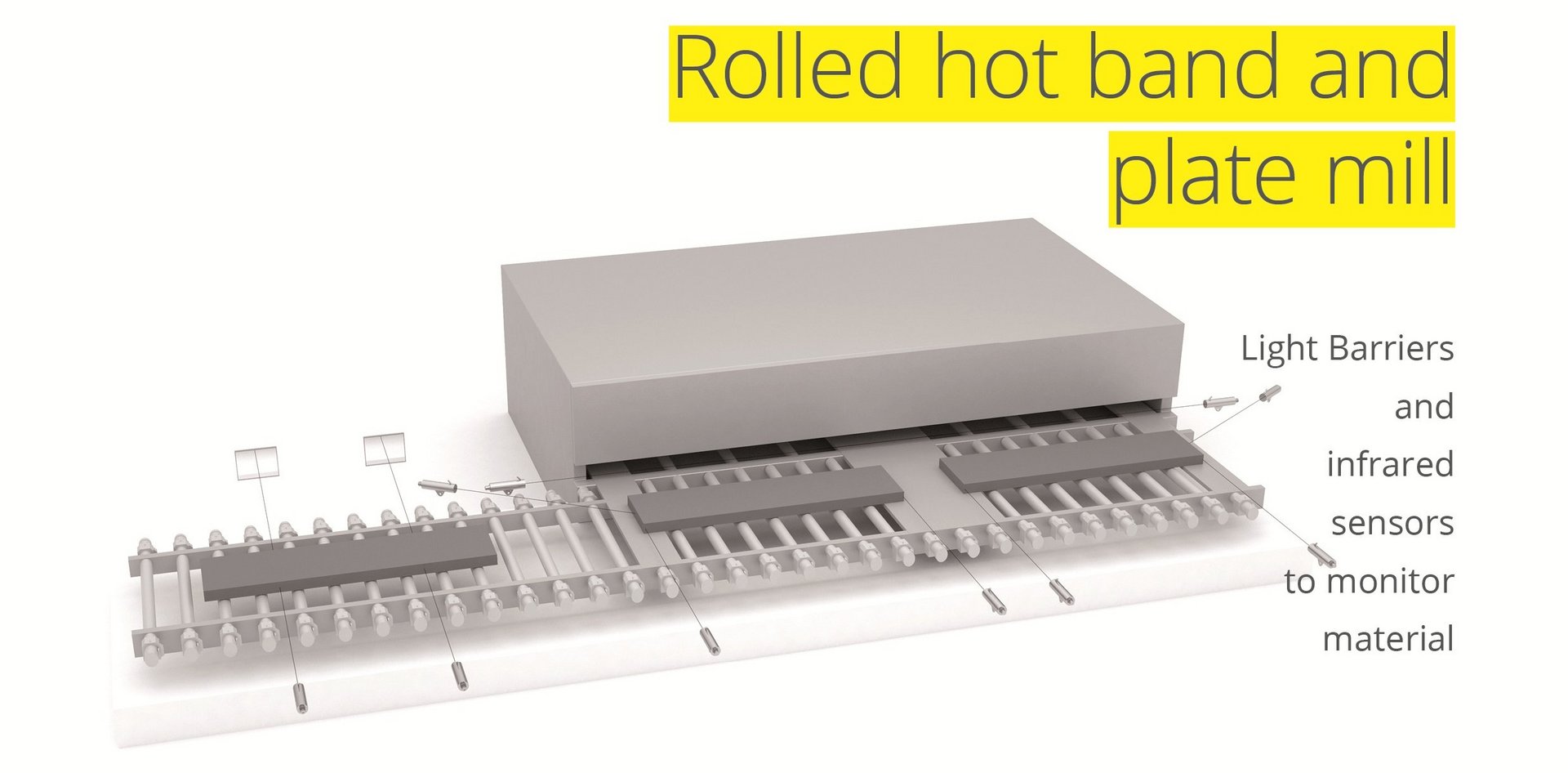

Application > Hot strip mill, sheet mills and blooming train

After the semi-finished material - e.g. a block - had been heated to the rolling temperature in a walking beam furnace, it is rolled to a defined measurement in the blooming train. This measurement is the tapping for the finishing train. Each end rolled product has its own tapping cross-section, which is related to the calibration, profile and individual passes on the rolls.

Proxitron infrared sensors are compact devices or equipped with optical fibre cable and lenses for high ambient temperatures of up to 600°C used worldwide for product monitoring in this area.

In addition, the OIL high-temperature infrared sensor protective tube system can be used in areas where detection from above is difficult due to heavy steam formation and the use of water. The protective tube system can be integrated into the roller conveyor from below.

Besides special inductive sensors, also pyrometers from Proxitron are used for contactless control and temperature measurement of the material, which is essential for the quality of the end product. Pyrometers from Proxitron can be exposed to the same harsh ambient conditions as light barriers and infrared sensors, and have a measuring range of up to 1800°C.

Do you have a similar application and would like to be advised?

Please fill out our application questionnaire and send it to sales(at)proxitron.de.

Our experts will answer you as soon as possible.

Your benefit, your advantage

Maintenance-free

High availability

Extremely robust

Infrared sensors: Actuation temperature variable from 250°C - 900°C

Light barriers: extreme functional reserve

More than 40 years of application experience worldwide

Cost-optimised with scaling depending on the installation location

Provision of samples for a test period

Application consulting / analysis