Application > Metal sheet batch control before cold press

Customer / Field / Equipment manufacturer

Metall processing – sub-supplier to the automotive industry

Application description

Before feeding the metal plate (sheet) into the cold press, it is necessary to check the fill level of the sheet batch. When the fill level has gone down to the minimum, a new batch it to be supplied.

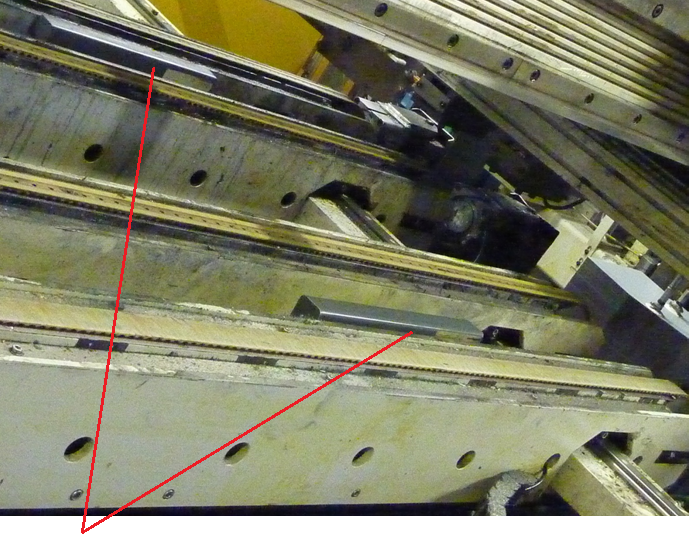

Sheets are lifted by means of a suction cup and laid down onto the conveyor for feeding into the cold press; here an additional position control must be performed.

Customer problem

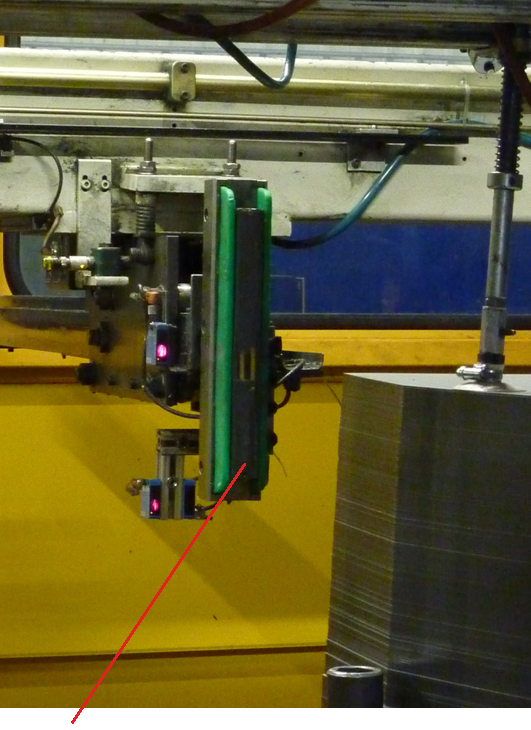

Level control can be performed only from the side, as sheets are picked up and lifted into the air.

The conveyor area where they are laid down may vary as a consequence of imprecise lifting of tilting sheets through the suction cup.

The performance of optical sensors in an oil-containing environment is unreliable.

Proxitron solution

Inductive proximity swtiches of IKU 031 design, being led to the batch from the side. Sensor is adjusted so as to detect material starting from a defined minimum level only. Two IKU 031 integrated into the conveyor for press feeding.

Advantages compared to previous solution or competition

An inductive proximity switch works properly regardless of the oil presence. Sensor switching can be adjusted to the desired filling level.

Thanks to its rectangular long sensing area, the sensor can detect sheets also when laid down onto the conveyor in a tilted position.

Do you have a similar application and would like to be advised?

Please fill out our application questionnaire for distance measurement and send it to sales(at)proxitron.de. Our experts will answer you as soon as possible.